Heinen doors can combine performance features on a bespoke basis. Depending on your needs, one or more performance features are added to the basic, robust METAL+ Inside door. Some performances are only available with the welded and mortar filled installation method.

The Metal+ Inside concept At the heart of every Heinen door

The basic performance features of the Metal+ Inside swing door

WELDED INSTALLATION AND MORTAR FILLING

Frequency of use

Up to 1,000,000 open/close cycles (max. level)

Mechanical resistance

M+7 (maximum normative level)

Service life of the door

15-year warranty on the door set

Burglary resistance

RC2 (with adapted cylinder)

Acoustic performance*

36dB single door

Airtightness*

Minimum L2

Thermal insulation*

Value between 1,7 and 1,9 W/m2K

*with automatic Kältefeind threshold

SCREWED INSTALLATION

Frequency of use

Up to 500,000 open/close cycles

Service life of the door

10-year warranty on the door set

Burglary resistance

RC2 (with adapted cylinder)

Airtightness*

Minimum L2

Thermal insulation*

Value between 1,7 and 1,9 W/m2K

*with automatic Kältefeind threshold

Combining bespoke performances features

A low total cost of ownership Heinen, the best-value solution in the long term

The Heinen product rangeUnique Metal+ Inside construction ensures a long service life.

Low maintenance, even in extreme conditions.

Easy repairability if damaged or vandalised, as the components are screwed onto the tubular structure (hinges and cover plates).

The Heinen warranty is defined by the installation method:

-15 years for doors installed with the welded installation clamps and mortar filling;

– 10 years for screwed doors.

A reliable robustness

Heinen owes its robustness to its “Metal+ Inside” door concept, the construction basis of each Heinen door.

- The Metal+ Inside concept stands out thanks to its modular design: each door has the same robust structure so that the basic performance features can be combined with a wide range of high-level performance features in a single door, whether it is fitted indoors or out!

- Another reason for this endurance is the use of screw-on hinges. This makes it possible to adjust the door in three dimensions after it has been fitted, guaranteeing that it is perfectly adapted to its location; ensuring maximum ease of use; and avoiding the malfunctions ordinarily caused by the heavy-duty use of the door. As the exterior plates are also screwed on, there is no need to change the entire door set: only the damaged part is replaced.

- Thanks to the unique Metal+ Inside concept, Heinen doors are constructed on the same basis and always have the same attractive look, regardless of their performance features. All Heinen doors are made to measure, up to 6m!

The great advantage of Heinen doors is that the performance features can be combined on a bespoke basis.

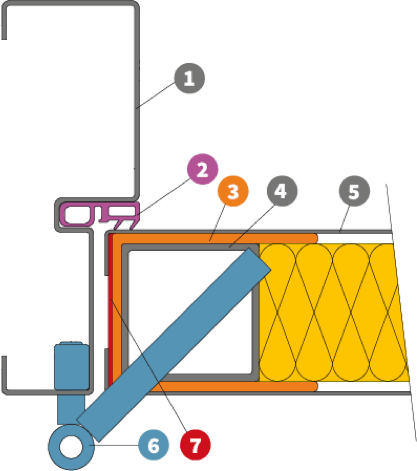

Components of the Metal+ Inside door

- Frame (steel sheet 15/10 or 20/10) covering the thickness of the reveal for an attractive finish (with optional thermal break).

- Double lip seal.

- Insulation around the edges of the door (with intumescent material for fire doors).

- Tubular steel structure (60 x 60 x 2 mm).

- Door skin comprising 15/10 galvanised steel sheet screwed into the tubular structure and individually replaceable.

- Self-lubricating hinges, adjustable and replaceable, screwed into the tubular door structure.

- Hyper-strong synthetic material (for optimum protection of the insulation or intumescent material incorporated into the door leaf).

Installation of the Metal+ Inside door

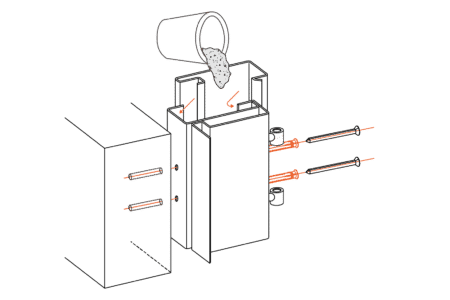

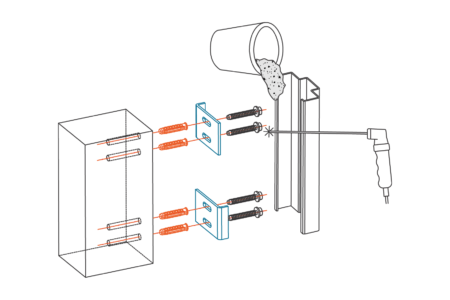

Installation of a hinged door with a mortared frame

The frame is first fixed mechanically with metal brackets (installation clamps) which are then welded to the frame. Finally, the frame must be completely filled with sealing mortar, which guarantees optimal protection in case of heavy use, aggression, fire and noise.

Available for the following performance features:

Metal +, Fire protection, Burglar proof, Bullet proof, Acoustic, Anti-panic.

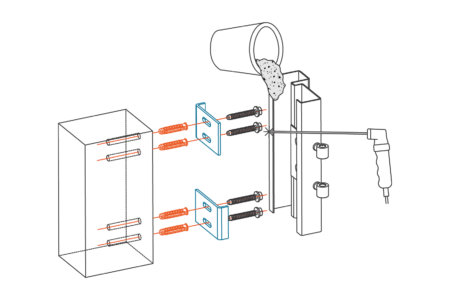

Installation of a hinged door with a screwed frame

The frame is mechanically fixed with screws and plugs. It is either pre-filled at the factory or empty. This method of installation ensures a quick and stress-free installation (no water or welding on site).

Available for the following performances:

Metal +, Fire protection, Burglar proof and Anti-panic

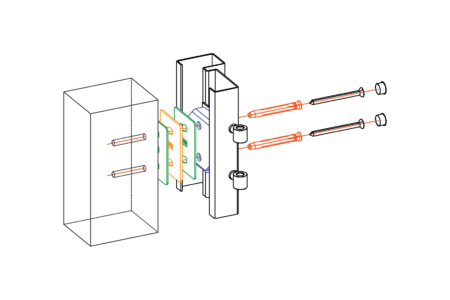

Installation of a two way door with a mortared frame

The frame is first fixed mechanically with metal brackets (installation clamps) which are then welded to the frame. Finally, the frame must be completely filled with sealing mortar, which guarantees optimal protection in case of heavy use, aggression or fire.

Available for the following performances:

Metal +, Fire protection untill 60 minutes

Installation of a surface mounted hinged door with a mortared frame

The frame is mechanically fixed with screws and plugs. It is either pre-filled at the factory or empty. Finally, the frame must be completely filled with sealing mortar, which guarantees optimal protection in case of heavy use, aggression or fire.

Available for the following performances:

Metal +, Fire protection untill 60 minutes